Arkil Specified Granular materials are produced at our quarry locations by means of blasting, crushing and screening into the required sizes. Arkil Specified Granular materials produced at our Pit locations are extracted from the pit face by excavator and screened into the required sizes.

Materials may vary in maximum size and percentage size distribution (grading) to suit the required applications and comply with the relevant specification. When producing these materials the aim is to always to have a finished product which is clean, hard and durable and capable of performing as required in an engineering environment and in accordance with specification..

These products have a wide range of required physical and chemical specification requirements depending on the end-use application. The main specifier of these products in Ireland is the National Roads Authority who set out each materials requirement in their Specification for Road Work Series 500,600 &800. Series 500 deals with Drainage and Pipe bedding materials, Series 600 with Earthworks materials and Series 800 with Sub-base materials.

Granular Fill material for use under concrete floors and footpaths is specified under Annex E of S.R. 21, 2016 which lists the physical, chemical and petrographic requirements of the material. This specification is aimed specifically at granular fill for use under concrete.

Production is managed under our ISO 9001 Quality Management scheme with all locations having either System 2+ or 4 levels of attestation of conformity as appropriate.

Key features and benefits

- Strong and durable to meet the demands of the civil engineering environment.

- Available in a range of sizes and gradings

- Made from local materials manufactured to the highest standards

- Large volumes can be accommodated

Technical specification

Aggregates

- EN 13242 Aggregates for Unbound and Hydraulically Bound Materials (S.R. 21)

- EN 13285 Unbound Mixtures Specification

- NRA Specification for Road Works

SR21 FAQ’s

1. What is SR 21?

SR 21 is a document listing the Irish Standard Recommendations on the use of the European Standard EN 13242. The document gives guidance on the best options to choose for specific engineering applications.

2. What is Annex E?

Annex E is a section of SR 21 which deals specifically with guidance on specifying aggregate properties for granular fill for use under concrete floors or footpaths.

3. When did SR 21 revision come into effect?

In March of 2016 the NSAI published the revised draft of S.R. 21. From date of publication the Standard becomes the only specification that should be used for granular materials to be used under concrete floors and footpaths

4. What is the documents full description/title?

SR 21: Guidance on the use of I.S. EN 13242:2013 – Aggregates for unbound and hydraulically bound materials for use in civil engineering work and road construction.

5. What new materials are covered in Annex E?

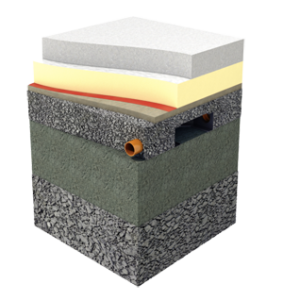

T.0 Struc

0-125mm Structural Layer for depths in excess 900mm

T.1 Struc

0/31.5mm (Crushed Rock) Structural Layer for depths less than 900mm

0/40mm (Crushed Gravel) Structural Layer for depths less than 900mm

T.2 Perm

4/40mm Gas Permeable Layer

T.3 Blind

0/4mm Blinding Layer

6. Where are these materials used?

Annex E Materials

T.0 Struc Unbound Granular Fill material is recommended for use where the fill material will be subject to substantial loading and /or dynamic loading, or the depth of fill is greater than 900 mm to the top of the subsoil.

T.1 Struc 0/31.5 Unbound Granular Fill (Crushed Rock) or 0/40mm Gravel is recommended for use where the overall depth of fill to subsoil is less than 900mm.

T.2 Perm 4/40mm Gas Permeable Layer is recommended in any building where a Radon Sump is to be operational in the sub-floor including all occupied new build projects, i.e. anywhere a person might be for work, leisure or residence.

T.3 Blind 0/4mm Blinding Layer is used when blinding the top surface of the T.2 Permeable material to ensure the radon barrier is not punctured and there is a level surface upon which to place the insulation and pour the concrete.

7. Are other materials suitable for under concrete floors and footpaths?

Annex E materials are the only materials that should be specified for use under concrete floors and footpaths.

8. Who is responsible for ensuring Granular Fill SR 21 Annex E:2016 is used?

It is the sole responsibility of the customer/site contractor to establish a system of traceability to ensure the correct material is used in the correct application.

9. How can it be traced back that the correct material was used?

IS 888 “Code of Practice for the procurement and use of unbound granular fill hardcore material for use under concrete floors” has also been published by the NSAI. This document covers all aspects of ordering, delivery, placement and traceability that may be required by the material user and specifier.

10. What are the Arkil product descriptions ?

S.R 21 Annex E, T.0 Structural (0/125mm)

S.R 21 Annex E, T.1 Structural (0/31.5mm)

S.R 21 Annex E, T.1 Structural (0/40mm)

S.R 21 Annex E, T.2 Permeable (4/40mm)

S.R 21 Annex E, T.3.Blinding (0/4mm)

11. What Arkil locations can supply this product?

We are happy to confirm that all relevant Arkil quarry locations have been inspected and tested and found to be in full compliance with S.R 21, and all other S.R’s such as

S.R 16 Aggregates for Concrete

S.R 17 Aggregates for Bituminous Mixtures and Surface Treatments

S.R 18 Aggregates for Mortar

12. What level of attestation is required under Annex E of SR 21?

The system of attestation and verification of performance has changed from System 4 (self-certification) to System 2+ (independent certification) for this particular end use aggregate. Annex E alone cannot be assessed for certification as only harmonized NSAI Standards can be assessed for CE marking of Systems of Factory Production Control so all accreditation will be to EN 13242 Aggregates for Unbound and Hydraulically Bound Materials.